Introduction

Effective inventory management is a cornerstone of a successful business. Whether you’re a small startup or a large multinational corporation, managing inventory efficiently can significantly impact profitability, customer satisfaction, and overall business operations. Business inventorying refers to the process of tracking and managing goods and materials within a business, ensuring that stock levels are maintained, and supply chains run smoothly.

This article explores the importance of business inventorying, the different types of inventory, best practices, and modern tools and techniques for inventory management. Whether you’re a retailer, manufacturer, or service provider, understanding how to manage your inventory effectively is essential for long-term success.

What is Business Inventorying?

Business inventorying refers to the method of recording, tracking, and managing a company’s inventory. Inventory represents the goods, raw materials, and products that a business holds to sell or use in production. Inventorying is crucial for several reasons, including managing costs, optimizing supply chains, preventing stockouts, and avoiding overstocking.

Inventory management isn’t just about counting stock; it’s about having the right items, in the right quantity, at the right time. Good inventorying practices ensure that businesses can meet customer demand without tying up too much capital in unsold goods.

Types of Business Inventory

In any business, inventory comes in different forms, depending on the industry and the nature of the business. The types of inventorying include:

1. Raw Materials

For manufacturing businesses, raw materials represent the basic inputs required to create finished products. These are materials that are yet to undergo any processing and are essential to the production process.

2. Work-in-Progress (WIP)

Work-in-progress inventory consists of goods that are in the process of being manufactured but are not yet completed. This can include partially assembled items, products waiting for additional parts, or items that require further processing.

3. Finished Goods

Finished goods are products that have completed the manufacturing process and are ready for sale. These items are typically stocked in warehouses until they are sold or shipped to customers.

4. Maintenance, Repair, and Overhaul (MRO) Inventory

MRO inventory includes items that are used in the operation, maintenance, and repair of machinery and equipment within the business. These items are not sold to customers but are crucial to business operations.

5. Transit Inventory

This type of inventory refers to products or goods that are in transit between locations, such as goods being shipped from suppliers to warehouses or from warehouses to retailers.

The Importance of Business Inventorying

Effective inventorying is more than just tracking stock. It has far-reaching implications for the overall success of a business. Here are a few key reasons why inventory management is critical:

1. Cost Control

Proper inventory management helps businesses avoid unnecessary expenses, such as overstocking or understocking. Overordering can tie up cash flow and lead to higher storage costs, while underordering can result in lost sales opportunities and customer dissatisfaction.

2. Improved Cash Flow

Having control over inventory allows businesses to optimize their cash flow. By reducing excess inventory, businesses can free up working capital and reinvest it into other areas of the business, such as marketing or product development.

3. Meeting Customer Demand

Stockouts—when products are unavailable for customers—can lead to lost sales and damage a business’s reputation. With proper inventory management, businesses can ensure that they have enough stock to meet customer demand without overstocking.

4. Supply Chain Optimization

Inventorying ensures that businesses maintain smooth operations across the supply chain. By tracking stock levels and suppliers, businesses can anticipate delays, streamline purchasing, and maintain a steady flow of goods.

5. Data Insights

Modern inventory systems provide valuable insights that can guide decision-making. Real-time data allows businesses to analyze trends, track product performance, and adjust inventory policies based on customer needs and market demands.

Best Practices for Business Inventorying

To maintain an efficient inventory system, businesses must follow several best practices. These strategies can help streamline inventory processes and improve overall operations.

1. Implement an Inventory Management System (IMS)

A robust IMS is essential for businesses to track inventory levels, monitor sales, and automate inventory-related tasks. Modern systems often include barcode scanning, RFID, and real-time updates, which reduce human errors and increase efficiency.

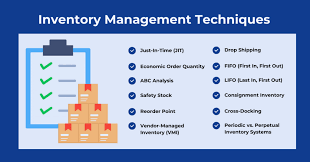

2. Use Just-In-Time (JIT) Inventory

JIT inventory management involves ordering goods and materials only when needed for production or to fulfill customer orders. This reduces excess inventory and storage costs. However, it requires precise forecasting and supply chain coordination to avoid stockouts.

3. Conduct Regular Inventory Audits

Frequent physical counts and audits ensure that recorded inventory levels match the actual stock. Businesses should implement a system for regular inventory checks, whether through cycle counting (counting portions of inventory regularly) or full physical counts.

4. Categorize Inventory

Not all inventory is created equal. Categorizing inventory by sales volume, shelf life, or profitability allows businesses to prioritize which items require more frequent monitoring. For example, fast-moving items should be tracked more closely to avoid stockouts.

5. Maintain a Safety Stock

Safety stock refers to extra inventory that acts as a buffer against unexpected demand spikes or supply chain delays. It’s important to calculate the optimal level of safety stock based on historical data, demand patterns, and lead times.

6. Monitor Demand and Forecast

Effective demand forecasting is crucial to preventing overstocking or stockouts. Businesses should use data analytics tools to analyze sales trends and predict future demand based on seasonality, market trends, and other factors.

Modern Tools and Technologies for Inventorying

Technology has revolutionized inventory management, providing businesses with tools to optimize their processes, reduce errors, and make more informed decisions. Below are some of the latest tools and technologies used in business inventorying:

1. Enterprise Resource Planning (ERP) Systems

ERP systems like SAP, Oracle, and Microsoft Dynamics integrate inventory management with other business functions such as finance, HR, and procurement. These systems provide a centralized database that ensures seamless data flow across the organization, enhancing decision-making.

2. Cloud-Based Inventory Management Software

Cloud-based inventory systems, such as TradeGecko, NetSuite, and Fishbowl, offer businesses real-time visibility into their stock levels and provide access to inventory data from anywhere. These platforms often include advanced features like automated replenishment, multi-location management, and integrations with e-commerce platforms.

3. Barcode and RFID Technology

Barcode and RFID systems have become standard in inventory management. Barcodes simplify stock tracking and inventory checks, while RFID offers the added advantage of tracking products in real-time without the need for manual scanning. Both technologies improve accuracy and speed in managing stock.

4. Inventory Management Apps

Mobile apps for inventory management, such as Stockpile and Sortly, allow businesses to track stock, manage orders, and generate reports directly from their smartphones or tablets. These apps are particularly useful for small businesses and warehouses with limited IT infrastructure.

5. Artificial Intelligence and Machine Learning

AI and machine learning algorithms are increasingly being used to predict demand and optimize stock levels. These technologies can analyze vast amounts of data to identify patterns, forecast demand more accurately, and even suggest the most efficient stock replenishment strategies.

Common Challenges in Business Inventorying

Despite the many tools and techniques available, businesses often face challenges in inventory management. Common issues include:

1. Overstocking and Understocking

Balancing the right amount of inventory is a tricky task. Overstocking ties up capital and increases storage costs, while understocking can lead to lost sales and customer dissatisfaction.

2. Data Inaccuracies

Manual inventorying processes are prone to errors. Discrepancies between physical stock and recorded levels can result in stockouts, overordering, and financial discrepancies.

3. Supply Chain Disruptions

Disruptions in the supply chain, whether due to supplier delays, shipping issues, or external factors like natural disasters, can severely impact inventory management.

4. Managing Multiple Locations

Businesses with multiple warehouses or retail locations may struggle to track inventory levels across different sites. Coordinating stock between locations is essential to ensure product availability and streamline fulfillment.

Conclusion

Business inventorying is a vital process that enables businesses to maintain operational efficiency, reduce costs, and satisfy customer demand. Whether you’re managing raw materials, finished goods, or transit inventory, understanding the fundamentals of inventory management and utilizing modern tools and technologies can help businesses optimize their operations. By implementing best practices, leveraging advanced software, and addressing common challenges, businesses can ensure that they have the right stock at the right time, ultimately leading to increased profitability and customer satisfaction.